Cone Crushers Gap Size Coarse And Fine Crushing

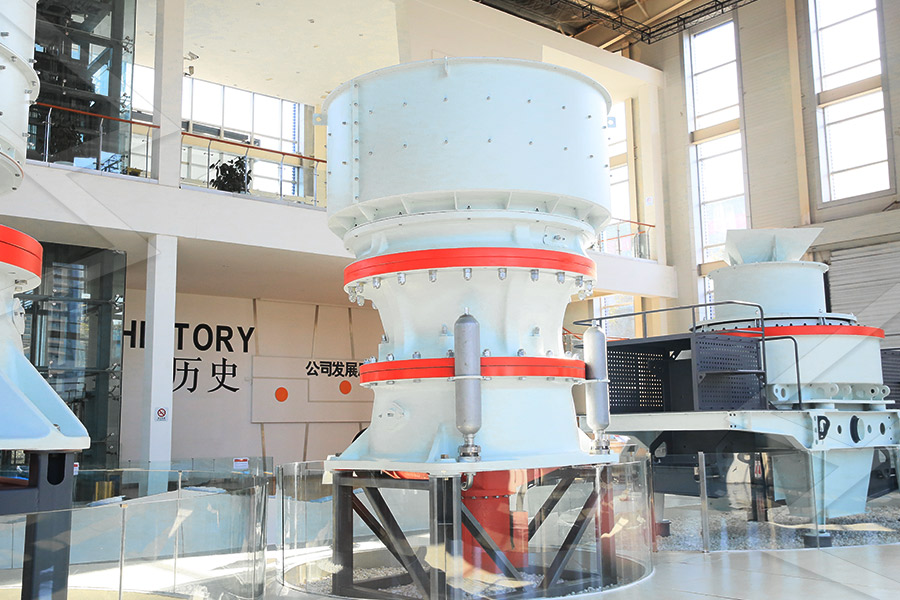

Chamber Optimization for Comprehensive Improvement of Cone

2021年3月15日 — This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of the cone crusher and optimize the crushing 2021年11月1日 — This paper describes a novel size reduction control strategy for cone crushers to address this problem The proposed control strategy is based on self Size reduction control in cone crushers ScienceDirect2017年1月1日 — At the coarse end, the coarsest size which has any chance of escaping breakage (ie the top in the product) varies almost linearly with CSS At the fine end, the Analysis of cone crusher performance with changes in Cone crushers are used for intermediate and fine crushing after primary crushing The key factor for the performance of a cone type secondary crusher is the profile of the crushing Cone Crusher an overview ScienceDirect Topics

Practical considerations on improved feeding

2024年9月24日 — and medium size F MF cone crushers A simple three section static splitter using the spider cap as the central compartment The material stream has to fall Three main factors are identified to promote the size reduction process occurring in a cone crusher, viz breakage modes, number of crushing zones and compression ratio The Size reduction in cone crushers 百度学术2019年7月3日 — Compressive crushing has been proven to be the most energy efficient way of mechanically reducing the size of rock particles Cone crushers utilize this mechanism CONE CRUSHER MODELLING AND SIMULATION2017年8月28日 — Original designs of cone crushers with hydraulic devices and doublejawed jaw crushers have been developed abroad during the past few years Hydraulic shaft New cone and jaw crusher designs Springer

.jpg)

kubria® Cone Crusher FLSmidth

Optimise your coarse, medium and fine crushing operations with this cuttingedge mining cone crusher The kubria® Cone Crusher features a hydraulically supported main shaft 2023年2月24日 — The gap between the mantle and concaves in a cone crusher is crucial for maintaining the proper size and shape of the crushed material If the gap is too large or too small, it can affect the crusher’s How to Adjust a Cone Crusher: A StepbyStep 2023年2月28日 — Cone crushers are wellsuited for producing a fine product size, while roll crushers are used for producing a finer product size and are often used in the mining industry Unlike primary and secondary The Complete Guide to Primary Crushing, Cone Crushers deliver a 4:1 to 6:1 reduction ratio A Cone Crusher with coarsestyle liners would typically have a 6:1 reduction ratio, though reduction ratios of 8:1 may be possible in certain coarse crushing applications Fine liner configurations typically have CMB Cone Crushers McLanahan

4 Types of Cone Crushers: What Are They and How to Select

2023年4月28日 — It perfectly combines crushing stroke, crushing speed, and the crushing cavity, so it has a higher output than other cone crushers The finished product has a more uniform particle size, higher strength, and fewer needles (below 8%), which is more in line with the requirements of highquality aggregateOptimise your coarse, medium and fine crushing operations with this cuttingedge mining cone crusher The kubria® Cone Crusher features a hydraulically supported main shaft and fixed upper shell Crushing takes place between the concaves in the crushing chamber and the mantle lined crushing cone, which is rotated by an eccentric drive in the kubria® Cone Crusher FLSmidth2018年12月26日 — 2 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance Content Chapter Title Page No 1 Crushers for Bulk Materials 3 2 Gyratory Crushers 8 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42Construction, Working and Maintenance of Crushers for 2022年1月21日 — Nordberg® HP Series™ cone crushers The world's most popular modern cone crushers Nordberg HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining Nordberg HP Series cone crushers – High performance

.jpg)

Crushing and Screening Handbook AusIMM

2021年6月24日 — 3 GP Series Cone Crushers 3 MP Series Cone Crushers 3 HP Series Cone Crushers 3 NP Series Impact Crushers 700mm coarse SD 285 t/m3 Abr 1227 g/t Cr 20 % 450 B13503V Load 75 % 450 Opening 100 mm 305 145 Setting 150 mm cone or impact crushing plants, with or without screens, and equipped with open or2023年1月20日 — Nordberg® HP Series™ cone crushers The world's most popular modern cone crushers Nordberg HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining Nordberg HP Series cone crushers – High performance 2023年8月11日 — This is important, especially in fine crushing Choke feeding maximizes the amount of multilayer crushing, and improves wear shape and crushing efficiency 1 Choke feed level for GP secondary crusher is at the level of the mantle fixing nut 2 Choke feed level for GP fine crusher is max 1 meter above the top bearing arrangementNordberg® GP Series™ cone crushers Wear parts 2021年11月1日 — Size reduction control of cone crushers has received fairly little attention over the past few decades Consequently, the most common control objective is still to regulate the crusher load (crusher power or crusher main shaft piston pressure) or the closed side setting (the shortest distance between crushing liners), not the actual size Size reduction control in cone crushers ScienceDirect

.jpg)

6 Types of Coal Crusher: Which Is Best for

2023年10月8日 — Note that cone crushers are not commonly used for coal This is because coal breaks easily and does not require the force that a cone crusher can provide Moreover, the cone crusher will produce more 2021年12月28日 — • The crusher should be choke fed so that the crushing chamber is full all the time This is important, especially in fine crushing Choke feeding maximizes the amount of multilayer crushing, improves the shape of the crushing cavity as it wears and improves the crushing efficiency => Choke feed level for an HP cone crusher isNordberg HP series cone crushers Wear parts 2021年12月17日 — • The crusher should be choke fed so that the crushing chamber is full all the time This is important, especially in fine crushing Choke feeding maximizes the amount of multilayer crushing, improves the shape of the crushing cavity as it wears and improves the crushing efficiency => Choke feed level for an HP cone crusher isNordberg HP series cone crushers Wear parts 2024年3月15日 — Ideal for Secondary and Tertiary Crushing Stages: Because of their high reduction ratio and precise control over the product size, cone crushers work particularly well in the secondary and tertiary stages of crushing For example, in a multistage crushing operation, a primary jaw crusher might reduce ore from a 1meter size to 100mm, and How Does a Cone Crusher Work and What is It? JXSC

.jpg)

SC220 Cone Crusher Athos Crushing and Screening

These cone crushers have the same footprint as the older 4 ¼ units measuring 2,9M(H) X 2,4M(W) They are extremely robust, heavy duty crushers and can accept a feed size of up to 230mm with the extra coarse cavity liners installed Short Head Fine 25 SC220 PRODUCT DATA Weight 26,120 Motor Power (kW) 220 Max Feed Size EC 230 CSS 2018年12月18日 — is important, especially in fine crushing Choke feeding maximizes the amount of multilayer crushing, improves the shape of the crushing cavity as it wears and improves the crushing efficiency => Choke feed level for an HP cone crusher is 300 mm or more above the feed plate • The feed must be distributed evenly 360º around the Nordberg HP series cone crushers Wear parts 2024年9月20日 — A unique roller bearing design reduces operating expenses by up to 50 percent while improving production and energy efficiency compared to bushing crushers The Kodiak ® cone crusher meets coarse and fine crushing application requirements and offers onthefly adjustability for easy operationAstec Kodiak® Cone Crushers AstecMax feed size 428 mm (17 in) Motor power of chambers 4 Sandvik CH890i and is a technologically advanced, highcapacity cone crushers designed for crushing applications in mines or large sized quarries CH890i Features Product data MC = Medium coarse; M = Medium; MF = Medium fine; F = Fine; Additional product information CH890i SRP

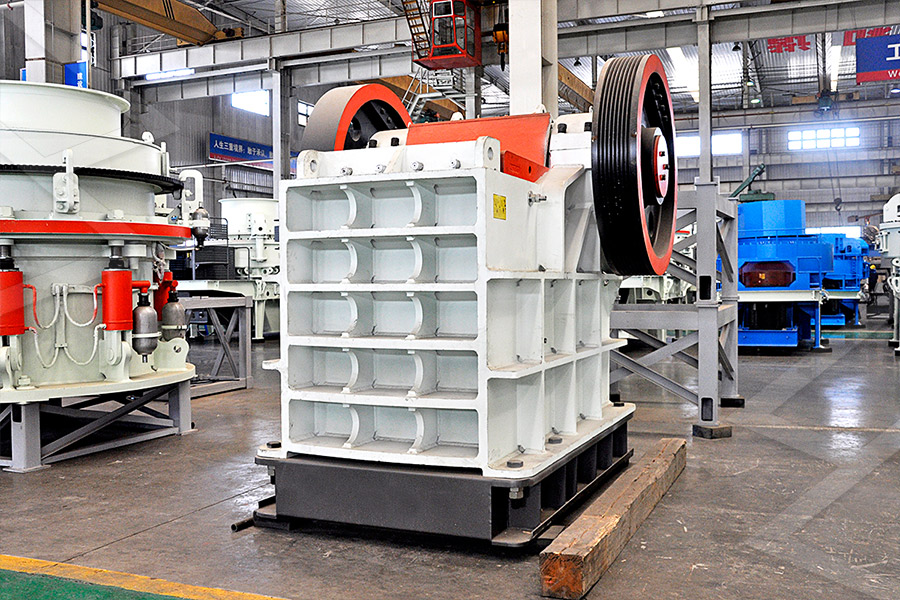

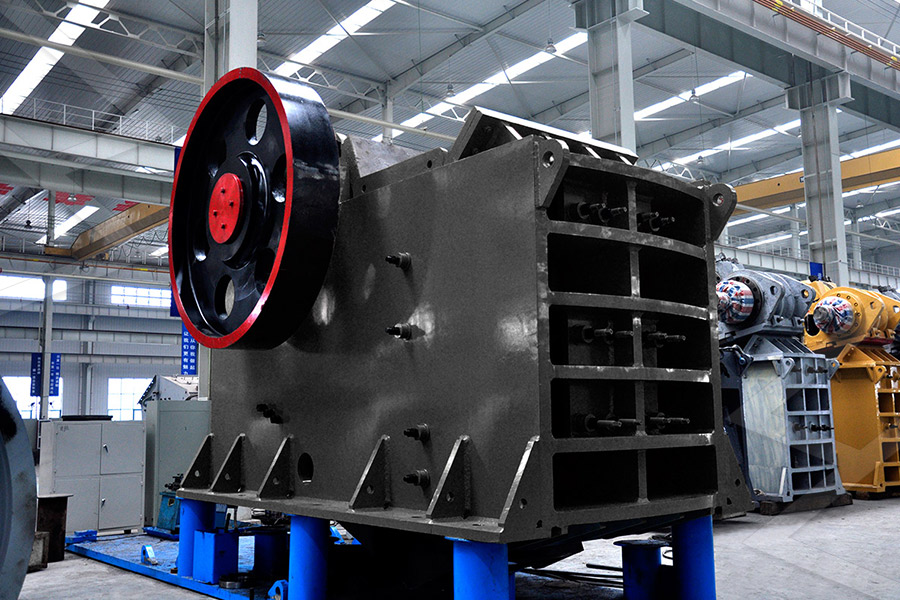

Jaw Crusher an overview ScienceDirect Topics

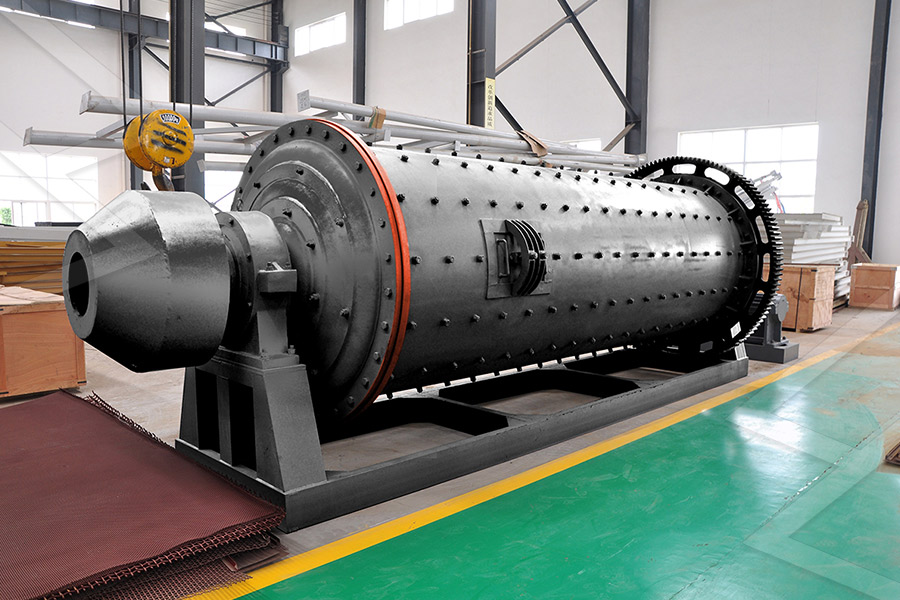

Overview of size reduction of raw materials of the cement industry Vipin Kant Singh, in The Science and Technology of Cement and Other Hydraulic Binders, 2023 421 Jaw crushers Jaw crushers are used for the primary reduction of hard and abrasive materials used for cement manufacture Jaw crushers 3 are of either Blaketype or Dodgetype and operate Former name: H6800 Cone crusher Several standard crushing chambers are available for each model The crushers can easily be matched to changes in production selecting the right crushing chamber and eccentric Sandvik CH660 Cone Crusher For Pebble Cone crushers are generally found in use for secondary, tertiary, and downstream crushing services, with jaw crushers and gyratory crushers used for primary crushing operations Jaw, Cone and Gyratory Crushers Cone Crushers (Parts of a Cone Crusher) 2019年4月18日 — When the mill feed size is reduced, through fine crushing, to about 80% passing 3 mm, the energy consumption will be minimized in a comminution chain of fine crushing and coarse rod grinding The An experimental investigation on rock

.jpg)

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 — Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap Additionally, gyratory crushers have a higher crushing ratio (meaning that they can crush large material into smaller pieces), a larger feed opening, and a more consistent product size and shape compared to cone crushers However, cone crushers have a more efficient crushing action for smaller materials but can produce more finesTypes of Crushers: What You Need to Know HUATAO GROUPThe crusher can crush the stone into fine particles by extrusion or bending, which is usually divided into fine crushing, medium crushing and coarse crushing Crushers mainly include jaw crusher, roller crusher, cone crusher, hammer crusher, impact crusher and Crusher an overview ScienceDirect Topics2024年3月1日 — 3 Cone crusher A cone crusher is a rock crusher used in the mining industry industry, industry for processing and production of nonmetallic materials Used in the mining industry for secondary crushing of stone, gold and other solid minerals Cone crushers have a coneshaped design that breaks larger rocks into smaller piecesWhat Machines Do Stone Crushing Plants Need? Fote

.jpg)

Crushing tools for cone crushers Spare parts Kleemann

The KX series of cone crushers are typically used as secondary and tertiary crushers In this case, the material entering the crusher is crushed between the rigid crushing shell and the moving crushing cone To achieve consistently high performance and a long service life, the entire wear surface of the crushing tool must be usedCone Crushers Gap Size Coarse And Fine Crushing T19:05:13+00:00Cone Crushers Gap Size Coarse And Fine Crushing agro 2017年4月7日 — When it comes to cone crushing material, a full chamber is the best practice {{image4a:lw:635}} • Correct application Cone crushers are versatile machines, but using them as they are set up to function is the best idea A 4:1 reduction ratio is a standard crusher applicationCaring for your cone crusher: A guide to optimising performanceCG series cone crushers have overhead receiving hoppers onto which the feeding conveyors loads the material The crusher produces maximum output in terms of production capacity when It is choke fed The Cone Crusher – Nesans Mining and Automation

.jpg)

5 Common Questions about Jaw Crushers

2019年5月30日 — Concrete; 5 Common Questions about Jaw Crushers Answered There are many types and styles of crushing equipment Kemper Equipment explains how to choose the right crusher for your operational 2022年11月21日 — Cone crushers are widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries The cone crusher has large crushing ratio, high efficiency, low energy consumption, uniform product size, and is suitable for medium and fine crushing of various ores and rocksJaw Crusher VS Cone Crusher: 9 Key Differences Zenith Nordberg® HP Series™ cone crushers are reliable rock crushing machines for all demanding quarrying, mining, and tunneling applications In a sizeclass comparison, Nordberg® HP™ crushers have a higher output capacity, higher density in the crushing chamber, better reduction ratio, and they produce higher onspec yield end products Nordberg® HP Series™ cone crushers Metso2016年1月18日 — The reduction ratio is driven by the Crusher Close Side Setting The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the character of the material, the amount of fines in the feed, and whether the crusher is being operated under chokefeed or regulated feed conditions It Crusher Close Side Settings 911Metallurgist

COMPARISON OF SECONDARY CRUSHING OPERATIONS THROUGH CONE

2020年9月20日 — The maximum feed size for cone and HSI crushers could be estimated at 12% of The 4S had an additional VSI crusher to 3S crushing Three coarse and three fine aggregate sizes were used in the 2023年2月28日 — The primary objective of crushing is to reduce the size of the materials for further processing Crushing is an energyintensive process that involves different types of equipment, such as crushers, screens, and conveyors Primary Crushing Primary crushing is the first stage of crushing that takes place at the mine or quarryPrimary and Secondary Crushing: Understanding the BasicsCrushing chamber Cone crushers consist of a fixed concave and a mantle that gyrates in an eccentric motion The mantle is continuously moving and provides a constantly changing gap at the bottom of the crushing chamber The smallest size of the gap is known as the closed side setting (CSS) and represents the smallest size of material that can be crushedUltimate Guide to Cone Crushers Foreman Equipment Ltd2024年9月22日 — Higher rotation speed and higher eccentric height for bigger crushing ratio Mantle and concave for coarse, medium and fine crushing can be installed in the same top cell assembly Higher rotation speed up to 800 RPM to obtain higher capacity Increased height of concave for improved crushing efficiency Automatic overload protectionCone Crushers Parker Plant

A review of modeling and control strategies for cone crushers

2021年8月15日 — The reader is referred to Svensson and Steer (1990) for a discussion about the physics involved in rock crushing inside a cone crusher; Bearman and Briggs, 1998, Lindqvist and Evertsson, 2006 for comprehensive insights into the effect of liner wear and feed properties on the operational characteristics of cone crushers; and Wills and Finch 2023年2月24日 — The gap between the mantle and concaves in a cone crusher is crucial for maintaining the proper size and shape of the crushed material If the gap is too large or too small, it can affect the crusher’s How to Adjust a Cone Crusher: A StepbyStep 2023年2月28日 — Cone crushers are wellsuited for producing a fine product size, while roll crushers are used for producing a finer product size and are often used in the mining industry Unlike primary and secondary The Complete Guide to Primary Crushing, Cone Crushers deliver a 4:1 to 6:1 reduction ratio A Cone Crusher with coarsestyle liners would typically have a 6:1 reduction ratio, though reduction ratios of 8:1 may be possible in certain coarse crushing applications Fine liner configurations typically have CMB Cone Crushers McLanahan

.jpg)

4 Types of Cone Crushers: What Are They and How to Select

2023年4月28日 — It perfectly combines crushing stroke, crushing speed, and the crushing cavity, so it has a higher output than other cone crushers The finished product has a more uniform particle size, higher strength, and fewer needles (below 8%), which is more in line with the requirements of highquality aggregateOptimise your coarse, medium and fine crushing operations with this cuttingedge mining cone crusher The kubria® Cone Crusher features a hydraulically supported main shaft and fixed upper shell Crushing takes place between the concaves in the crushing chamber and the mantle lined crushing cone, which is rotated by an eccentric drive in the kubria® Cone Crusher FLSmidth2018年12月26日 — 2 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance Content Chapter Title Page No 1 Crushers for Bulk Materials 3 2 Gyratory Crushers 8 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42Construction, Working and Maintenance of Crushers for 2022年1月21日 — Nordberg® HP Series™ cone crushers The world's most popular modern cone crushers Nordberg HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining Nordberg HP Series cone crushers – High performance

Crushing and Screening Handbook AusIMM

2021年6月24日 — 3 GP Series Cone Crushers 3 MP Series Cone Crushers 3 HP Series Cone Crushers 3 NP Series Impact Crushers 700mm coarse SD 285 t/m3 Abr 1227 g/t Cr 20 % 450 B13503V Load 75 % 450 Opening 100 mm 305 145 Setting 150 mm cone or impact crushing plants, with or without screens, and equipped with open or2023年1月20日 — Nordberg® HP Series™ cone crushers The world's most popular modern cone crushers Nordberg HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining Nordberg HP Series cone crushers – High performance 2023年8月11日 — This is important, especially in fine crushing Choke feeding maximizes the amount of multilayer crushing, and improves wear shape and crushing efficiency 1 Choke feed level for GP secondary crusher is at the level of the mantle fixing nut 2 Choke feed level for GP fine crusher is max 1 meter above the top bearing arrangementNordberg® GP Series™ cone crushers Wear parts