Gold Ore Quartz Concentrator

Gravity Concentration of GoldBearing Ores and Processing

2024年9月5日 — The potential of any gold ore for gravity recovery is assessed using the standard gravity recoverable gold (GRG) test This threestage sequential process 2024年9月20日 — This study investigates the optimization of placer gold ore processing using a laboratoryscale Knelson concentrator through response surface methodology (RSM) Enrichment of placer gold ore through Knelson concentrator 2020年7月1日 — As a kind of gravity separation equipment, Nelson concentrator is more and more favored by mines because of its high enrichment ratio, high recovery rate and Research and Application of Nelson Concentrator in 2017年7月10日 — Key words: quartz vein type gold deposit, coarse grained gold, Knelson concentrator, Knelson gravity separationflotation, Knelson gravity separationfull mud Application of Knelson Gravity Concentration in Quartz Vein

Processing a Gold Ore from Hainan Province Using Knelson

Abstract: The experimental study of Knelson gravity concentrationflotation technology of a quartzvein type gold ore in Hainan Province was carried out The GRG(gravity 2020年8月12日 — As a kind of gravity separation equipment, Nelson concentrator is more and more favored by mines because of its high enrichment ratio, high recovery rate and Research and Application of Nelson Concentrator in Beneficiation Test 2013年5月1日 — This work investigated using a laboratory scale Knelson Concentrator with a dry feed, and air being used to replace water as the fluidising medium and sizebysize The potential for dry processing using a Knelson Concentrator2021年9月24日 — The scientific novelty of the work lies in the extraction of gold from refractory ore with sorption activity using sequential processes of gravity separation and Integrated Technology for Processing GoldBearing Ore

.jpg)

Research and application of a Knelson concentrator: A review

2020年6月15日 — The Knelson concentrator (KC) is widely used in gold ore and other precious metal ore processing technology because of its excellent separation 2020年6月1日 — The Knelson concentrator (KC) is widely used in gold ore and other precious metal ore processing technology because of its excellent separation performanceResearch and application of a Knelson 2006年3月13日 — The occurrence of gold in th e ore (a) free gold particles in quartz matrix, (b) gold particles associated with chalcopyrite and pyrite, (Au: gold; Cp : Chalcopyrite; Py: Pyrite; Sp : Sphalerite Gold recovery from Mastra gold ore by Falcon centrifugal concentrator2019年10月23日 — The Knelson gold concentrator has great advantages in the gravity separation of quartz vein type gold ore and has been applied to the beneficiation process by more and more gold plants Among them, Quartz Vein Gold Beneficiation Process JXSC

Performance evaluation of processing claycontaining ore in

2020年6月15日 — Artificially mixed slurries of magnetite, quartz and clay were used for the experiments The most common application of Knelson concentrator is in gold processing industry since it has the ability to recover 96% of free liberated gold Influence of clays on the slurry rheology and flotation of a pyritic gold ore Appl Clay Sci, 136 2013年5月1日 — The Knelson concentrator (KC) is widely used in gold ore and other precious metal ore processing technology because of its excellent separation performance The development history and types of KCs are reviewed in this paper The feed used was a synthetic mixture of tungsten and quartz, used to mimic a gold ore The response surface The potential for dry processing using a Knelson Concentrator2020年6月15日 — The Knelson concentrator (KC) is widely used in gold ore and other precious metal ore processing technology because of its excellent separation performance The development history and types of KCs are reviewed in this paper Ringbyring analysis and models of retained mass of quartz in a laboratory Knelson Concentrator Research and application of a Knelson concentrator: A reviewThe APT GoldKacha concentrator is a small scale gold concentrator; a complete, simple and robust processing solution for the high recovery of both coarse and fine precious metals from dump tailings, rubble beds alluvial sands Run via generator, no clean water required, suited to all kinds of terrain and environmental conditions, ideal for GoldKacha Gold Concentrator Small Scale Gold Concentrator

.jpg)

(PDF) Recovery of Gold from a FreeMilling Ore by Centrifugal Gravity

4 CONCLUSION The mineralogical analysis of the Mastra gold ore has shown that gold occurs as associated with quartz and sulphide minerals, and as particles of 1300 μm in size The gold particles, having a size of ≥150 μm, were estimated to be 50% of the gold present in the ore, indicating its potential for gravity recovery2020年4月1日 — This ecofriendly technique with low installation requirements and operation cost is widely used in the gold ore processing industry (Clifford, 2009) The Knelson Concentrator (KC) is a vertical bowltype centrifugal device that was invented and commercialized in 1980 by Byron Knelson (Knelson, 1992, Knelson and Edwards, 1990)Ringbyring analysis and models of retained mass of quartz 2021年9月24日 — The article is devoted to the development of technology for the processing of goldbearing raw materials In the process of performing the work, the following methods were used: gravity recoverable gold test (method of Knelson, Canada), stage test of the Institute Technologies of mineral separation (Russia) (determination of the optimal size of Integrated Technology for Processing GoldBearing Ore2023年7月18日 — The occurrence of gold in the ore (a) gold particle associated with galen and sphalerite, (b) gold particles associated with galen, pyrite and chalcopyrite in quartz, (Au: gold; Cp: Chalcopyrite Gold recovery from Mastra gold ore by Falcon

Separation behavior of Falcon concentrator for the recovery

2023年3月15日 — Further, the recovery of residual gold and other associated values from gold mine tailings is reported [6], [10], [21] Fu et al [10] developed an integrated model to recover the residual gold and iron values from cyanideleached gold tailings by following the reduction roasting and leaching process, wherein 942% recovery of gold was achieved911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has Metallurgists Mineral Processing Engineers2023年7月18日 — Concentrator for the recovery of gold from ore was reported The results of mineralogical analysis The occurrence of gold in the ore, a) gold particles in quartz matrix, b) gold particles “Research Note” RECOVERY OF GOLD FROM A FREE 2022年6月29日 — Gold doesn’t dissolve in anything reasonable, if it’s still there in the morning you have gold I’d think hard before going into that test You can easily destroy the value of your piece by getting overeager to figure out what it is What is Gold in Quartz Worth? Gold prices change daily Hourly, evenGold in Quartz: Understanding the Value of Gold Found inside Quartz

.jpg)

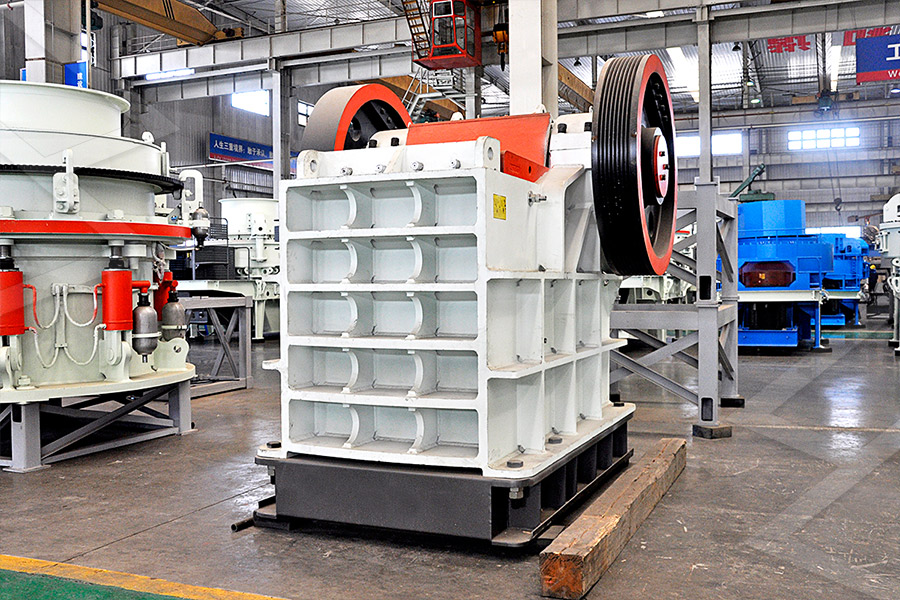

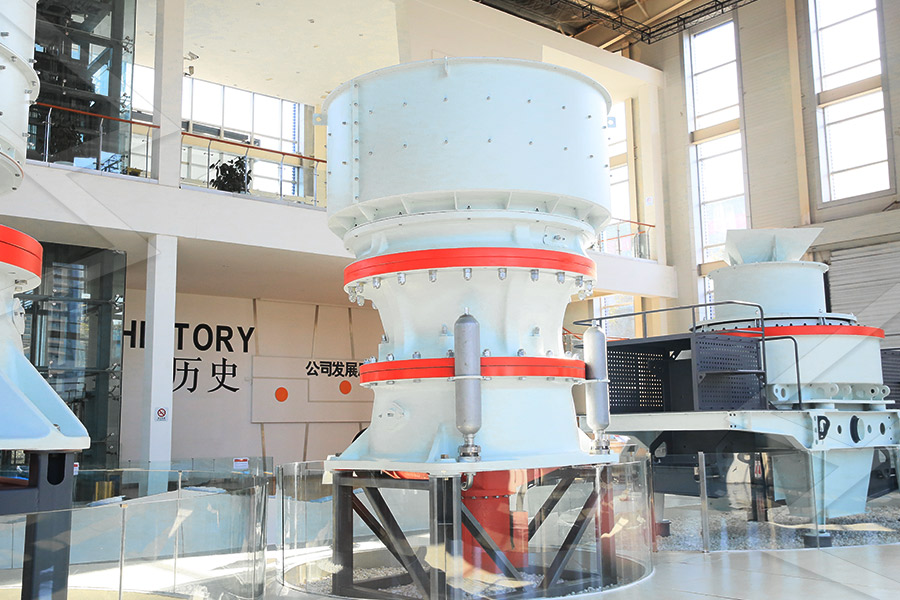

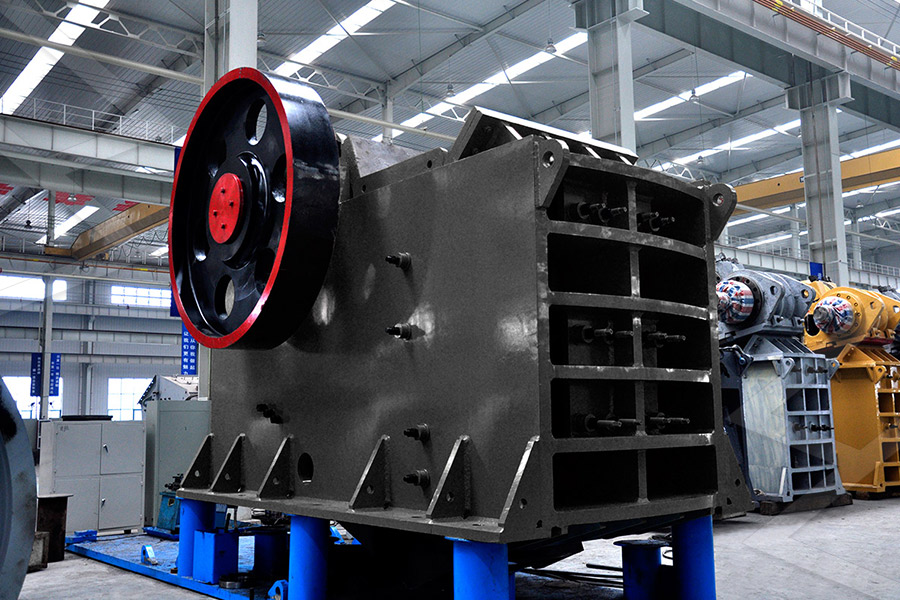

Small Scale Gold Mining Equipment JXSC Mineral

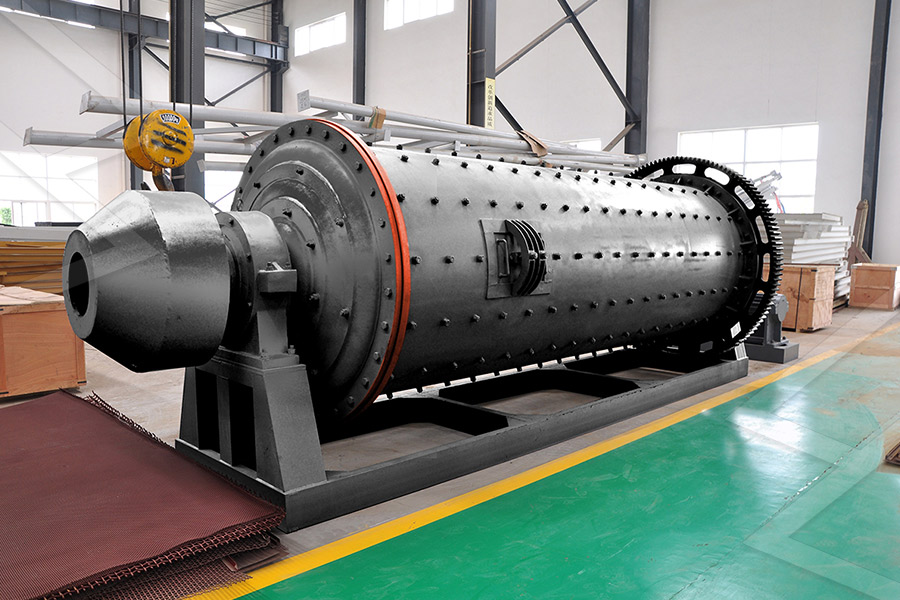

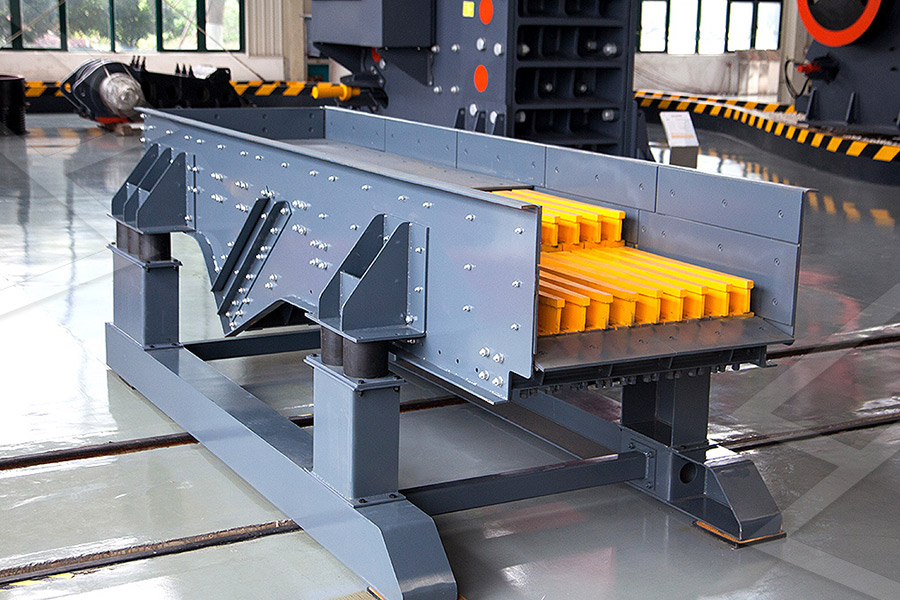

2 天之前 — Main Equipment: Ball mill, gold centrifugal concentrator, shaking table Flowchart explanation for 2tph rock gold processing plant This is a 2 TPH rock gold processing plant site from an Egyptian customer, it’s configured with a ball mill, gold centrifugal concentrator, and shaking table Ore in transit bin is sent to ball mill via vibrating feeder and belt The mineralogical analysis of the Mastra gold ore has shown that gold occurs as associated with quartz and sulphide minerals, and as particles of 1300 μ m in size may be achieved in a The flowsheet for gravity recovery tests using a Falcon concentrator 2024年2月19日 — Australian Goldfields In the Australian Goldfields, goldquartz connections were also evident, especially starting with the 1851 discovery in New South Wales and VictoriaHere, the Ballarat and Bendigo regions became celebrated for their large quartz reef systems containing goldMining operations, often conducted underground, targeted these Quartz and Gold: A Mineralogical Love Story Rock Seeker2024年9月23日 — quartz, mica and pyrite, with signifi cant kaolinite clay and talcrelated magnesium silicate content within the weathered zones A goldenriched oxide zone on the Phu Kham orebody was the resource for the heap leach gold mine which was built and operated by Phu Bia Mining during the 2005 to 2010 periodRecent Process Developments at the Phu Kham Copper

Gold CIP/CIL Processing Plant Solution Dasen Mining

5 天之前 — Dasen provides gold ore CIP CIL processing plant and also equipment manufacturing solution with benefits of ultra low power consumption, easy to use and high output rate varying ore and concentrator conditions necessitate different gold cyanide leaching methods and technical parameters Indian Client Visits Dasen Mining for 5 天之前 — The gold centrifugal concentrator rotates at a high speed, generating a high “G” force, which can separate small gravity recovery gold (less than 50 microns) The centrifugal concentrator can also recover the Gold Centrifugal Concentrator JXSC Machinery2015年3月1日 — Tungsten–quartz mixture was processed dry using a lab scale Knelson Concentrator The feed used was a synthetic mixture of tungsten and quartz, used to mimic a gold ore The response surface method and central composite design techniques were used to design the experiments and to model the results, with the experimental A design of experiments investigation into dry separation using 2022年12月20日 — Oat gold, fine gold, micron gold (micros), and gold dust are all terms used for the smallest forms of gold These minute particles get lodged under rocks and pebbles and collect on the top of bedrock They Fine Gold Recovery With a Blue Bowl

Particle Classification in the Enhanced Gravity Field Using the

2023年10月5日 — The particle classification in the enhanced gravity field generated by the Knelson concentrator was studied in this paper Three main test parameters, namely rotation speed, backwash water pressure, and solid mass percentage, that affected the classification performance of the Knelson concentrator for the classification tests of quartz and 2019年4月25日 — The useful components are single and mainly natural gold, the content of harmful component is low, and the gold grade of original ore is AU 5 3G / T Crushing: three stages and one closed circuit Grinding: one closed circuit( 200 mesh takes 60%) Classification: FX350 hydroclone(2 sets) Gravity separation: KCCD20MS Knelson gold Knelson Concentrator in Gold Mining Plant JXSC Machine2022年12月19日 — Indonesia is famous of its primary and alluvial gold ore One the primary gold ore deposit is located at Kotanopan, Mandailing Natal Districts, North Sumatera Province Primary ore is characteristically available in fine particle size (75µm) associated with quartz or complex sulfide ores However, the concentration ofCentrifugal Concentration of Mandailing Natal North 2017年2月9日 — Gold concentrates tend to be mostly iron, so they are also known as “black sands” Gold concentrates are also made by grinding down ore, quartz, or other productive rock types into sand This procedure is much faster and easier than panning, but the tradeoff is a final product that has less gold “concentrated” withinAsk MGS: What are Gold Concentrates? Manhattan Gold

.jpg)

The design of a mobile concentrator plant for gold

The system design was modelled using CAD software (solidworks) The design incorporated a multiple stage sluicebox and a mechanically agitated cyanidebased leaching drum Based on the design analysis and calculation, maximum mass of gold ore material needed to be processed at a time on the sluicebox was 415 kgSluice Goose Industries is in business to research and invent new Gold processing equipment technologies to separate Gold from Placer mineral deposits mineralized gold and gold less than 70 microns In fact, the GOLDROP’s Magnet Sluice captures high grade gold ore no other device can! This makes the GOLDROP a valuable tool to extract Sluice Goose Industries Gold Recovery, Gold Processing2023年12月15日 — The operation management of a gold ore concentrator is a key factor to ensure the success of the enterprise It covers many aspects such as process flow management, equipment maintenance management, quality management, safety and environmental management, production planning and cost control By implementing Guide of Gold Ore Concentrator Operation and Management2020年10月21日 — For example, a gold concentrator processes typical irongold ore, with a processing capacity of 200 tons/day and a gold grade of 10 grams/ton All ores are calcined in a rotary calciner The technical measures to intensify the flotation of goldbearing iron ore are similar to the flotation of goldbearing quartz vein ore4 Extraction Processes for GoldPyrite Ore miningpedia

Processing of gold from Mastra (GümüşhaneTurkey) ore by

2004年6月15日 — In this study, the mineralogical properties and the amenability of Mastra (GümüşhaneTurkey) gold ore to gravity recovery using a Knelson Concentrator were examined2024年9月24日 — 1 The grade of goldbearing ore: the higher the gold content in gold ore, the higher the grade of gold concentrate If the grade of gold ore is low, the gold content in the extracted gold concentrate will be Factors Affecting Gold Concentrate Grade And 2024年1月3日 — rite, pyrite, quartz, calcite minerals occur as accessory minerals in the ore (Tüysüz et al, 1995) It was reported that the ore contains gold entities with a mean diameter of 30 microns and The Use of Falcon Concentrator to Determine the Gravity 2022年6月13日 — Goldcontaining ore processing technology has been developed by using chemical, Xray phase, mineralogical, Xray fluorescence analyses The results of experiments on the gold recovery from a concentrate with a particle size of 10 and 4 µm are presented, including options for direct cyanidation without preliminary oxygen oxidation, Study of the Technology for Gold Recovery from Gravity

Common Gold Ore Beneficiation Process JXSC Machine

2024年9月21日 — The quartz vein type gold ore beneficiation process is mainly cyanidation method and flotation method The cyanidation method is a method in which gold or silver in gold or silver ore is leached by using an aqueous solution of an alkali metal cyanide as a solvent, and then gold and silver are extracted from a solution containing gold or silver2022年3月1日 — A jig is a mechanical concentrator that operates a fluidised bed, where stratification forms a sequence of layers that offers increasing resistance, from top to bottom, to the particles of lower density and higher size than those of particles that comprise the bed Case 9 Thiocyanide was used to dissolve gold from gold ore associated with A systematic review of sustainable gold extraction from raw 2018年1月1日 — In this study, recovery of gold from massive sulphide CuAu ore from Black Sea region was aimed by using gravity concentration methods Falcon concentrator and shaking table were used in gravity Gold recovery from CuAu ore using gravity concentration 2019年7月12日 — 3 Goldbearing quartz vein ore containing a small amount of sulfide This ore is most common in goldbearing quartz veins ore and generally contains 1% to 5% of metal sulfides According to the state of gold production, it can be divided into two types: one is associated with sulphide ore, another is associated with gangue minerals such as quartz5 Easily Extracted Gold Ores and 8 Processing Methods JXSC

(PDF) Gravity Concentration in Artisanal Gold Mining

2020年11月18日 — The Knelson concentrator (KC) is widely used in gold ore and other precious metal ore processing technology because of its excellent separation performance The development history and types of 2020年6月1日 — The Knelson concentrator (KC) is widely used in gold ore and other precious metal ore processing technology because of its excellent separation performanceResearch and application of a Knelson 2006年3月13日 — The occurrence of gold in th e ore (a) free gold particles in quartz matrix, (b) gold particles associated with chalcopyrite and pyrite, (Au: gold; Cp : Chalcopyrite; Py: Pyrite; Sp : Sphalerite Gold recovery from Mastra gold ore by Falcon centrifugal concentrator2019年10月23日 — The Knelson gold concentrator has great advantages in the gravity separation of quartz vein type gold ore and has been applied to the beneficiation process by more and more gold plants Among them, Quartz Vein Gold Beneficiation Process JXSC

.jpg)

Performance evaluation of processing claycontaining ore in

2020年6月15日 — Artificially mixed slurries of magnetite, quartz and clay were used for the experiments The most common application of Knelson concentrator is in gold processing industry since it has the ability to recover 96% of free liberated gold Influence of clays on the slurry rheology and flotation of a pyritic gold ore Appl Clay Sci, 136 2013年5月1日 — The Knelson concentrator (KC) is widely used in gold ore and other precious metal ore processing technology because of its excellent separation performance The development history and types of KCs are reviewed in this paper The feed used was a synthetic mixture of tungsten and quartz, used to mimic a gold ore The response surface The potential for dry processing using a Knelson Concentrator2020年6月15日 — The Knelson concentrator (KC) is widely used in gold ore and other precious metal ore processing technology because of its excellent separation performance The development history and types of KCs are reviewed in this paper Ringbyring analysis and models of retained mass of quartz in a laboratory Knelson Concentrator Research and application of a Knelson concentrator: A reviewThe APT GoldKacha concentrator is a small scale gold concentrator; a complete, simple and robust processing solution for the high recovery of both coarse and fine precious metals from dump tailings, rubble beds alluvial sands Run via generator, no clean water required, suited to all kinds of terrain and environmental conditions, ideal for GoldKacha Gold Concentrator Small Scale Gold Concentrator

.jpg)

(PDF) Recovery of Gold from a FreeMilling Ore by Centrifugal Gravity

4 CONCLUSION The mineralogical analysis of the Mastra gold ore has shown that gold occurs as associated with quartz and sulphide minerals, and as particles of 1300 μm in size The gold particles, having a size of ≥150 μm, were estimated to be 50% of the gold present in the ore, indicating its potential for gravity recovery2020年4月1日 — This ecofriendly technique with low installation requirements and operation cost is widely used in the gold ore processing industry (Clifford, 2009) The Knelson Concentrator (KC) is a vertical bowltype centrifugal device that was invented and commercialized in 1980 by Byron Knelson (Knelson, 1992, Knelson and Edwards, 1990)Ringbyring analysis and models of retained mass of quartz 2021年9月24日 — The article is devoted to the development of technology for the processing of goldbearing raw materials In the process of performing the work, the following methods were used: gravity recoverable gold test (method of Knelson, Canada), stage test of the Institute Technologies of mineral separation (Russia) (determination of the optimal size of Integrated Technology for Processing GoldBearing Ore